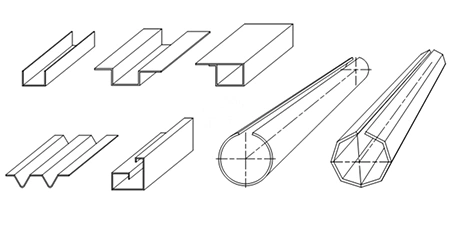

Sheet Metal Bending

Flexibility

The most flexible option (ease of reconfiguration) is the bending technology using a CNC hydraulic press brake: switching from one side to the other requires minimal time and effort—simply write a new program and upload it to the machine controller or load an existing program, rotate or replace the die, and, if necessary, change the punch. Furthermore, the free bending technology is versatile, allowing different thickness sheets to be bent on the same equipment.

Technological Process

Bending, applicable to sheets ranging from 0.5 mm to over 10 mm, is a cold stamping operation involving residual deformation of flat sheets. The sheet is initially positioned over a die (or V-block) secured at preset backstops; then force is applied to the piece of sheet metal using an appropriate punch. The required deformation to achieve the desired bend depends on the yield strength of the sheet, its thickness, and the length and direction of the bend.

Equipment

ALTAL provides professional metal bending services based on customer drawings using a CNC press brake. Our equipment is characterized by high precision, allowing bending of metals with thicknesses ranging from 0.5 to 10 mm. Free bending enables the production of parts with bends at various angles and in different directions. To achieve optimal results, our specialists may employ various bending methods or pre-straighten products before the main deformation procedure. Our machinery facilitates the assembly of dies and molds to create products according to desired specifications. Pricing depends on thickness, length, and the number of bends, as well as the machine operating time during processing and the order volume. The maximum sheet length we can handle is limited to 2500 mm.

Professionalism

ALTAL executes professional metal bending according to customer specifications using CNC press brake technology. Our equipment offers high precision and the capability to bend metals of various thicknesses from 0.5 to 10 mm. Free bending allows for the creation of components with bends in different directions and angles. To ensure the best outcomes, our experts may utilize various bending techniques or pre-stretch materials before the main deformation process. Our machinery simplifies the assembly of molds and dies for producing products to the desired design. Pricing is contingent on thickness, length, and the number of bends, along with machine operating time and order size. The maximum sheet length we can manage is 2500 mm.

Specifications

| Hydraulic Press | |

|---|---|

| Parameters | |

| Nominal Force, kN | 1250 |

| Table Length, mm | 2500 |

| Maximum Open Height, mm | 385 |